Smart warehousing

Warehouse management scheme based on RFID technology

1. Warehouse RFID management plan

1. Overall construction principles and goals

The overall construction of the RFID warehouse management program follows the following principles:

Ø Do not change the existing business process;

Ø Improve existing work efficiency;

Ø Practical, advanced, safe and reliable;

Ø Realize tangible economic returns for the company;

Ø Provide the company with added value besides controlling management costs, such as improving user experience, etc.

2. Construction content

Based on the current RFID product implementation experience, preliminary suggestions are as follows:

1) Use passive tags to manage the inventory of goods and shelves in the cargo area;

2) Use a wireless RFID card reader to manage the forklift's goods in, out and inquiries;

3) Use a fixed RFID card reader to realize the management of the entry and exit of goods including forklifts;

4) Use a handheld card reader to manage and query the entire warehouse operation process;

2. Implementation of RFID management plan

Management process of cargo area based on RFID technology

Management process of cargo area based on RFID technology

①. Use a fixed reader to write the details of the goods in the warehouse (not only can the product specifications and performance be written on the label, but also the specific shelf location of the goods to be placed for easy search and inventory.) Enter the background system.

②. During the handling operation, the wireless card reader installed on the forklift can identify the shelf number of the item to be placed in the warehouse for accurate storage.

③. It is unnecessary to manually fill in the warehousing list, and the warehousing list can be generated directly on the APP and uploaded directly to the background via GPRS or WiFi, keeping the background data consistent.

2. Use the wireless card reader on the forklift to realize item inquiry and storage

Use the wireless card reader on the forklift to realize the item inquiry and outgoing and storage

①, Android's wireless card reader on the forklift can read electronic tags on shelves and items from a long distance (distance up to 10 meters)

②, through the APP on the wireless card reader, the precise location of the items to be entered and exited from the warehouse can be automatically inquired;

③, without manual search, you can find the location of the items to be out or in the warehouse from a long distance, avoiding accidentally moving in

3. Use a fixed RFID card reader and a sense of ground to realize the management of the forklift and the entry and exit of the goods

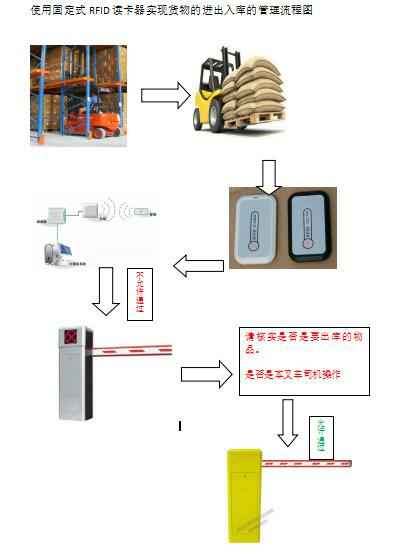

Use a fixed RFID card reader and ground sense to realize the management of forklifts and goods in and out of the warehouse

The fixed card reader installed at the exit, identifies the label on the forklift and the pallet, and compares the shipping data in the background. The goods to be shipped are automatically lifted and released, and the manager will be notified for inquiries if the goods are not to be shipped.

can also manage drivers and vehicles (requires background software support)

Scan code and wechat

Scan code and wechat